Cold Drawn Flat - Square - Wiping Irons

Quality : ST-37-2

Standard : EN10278

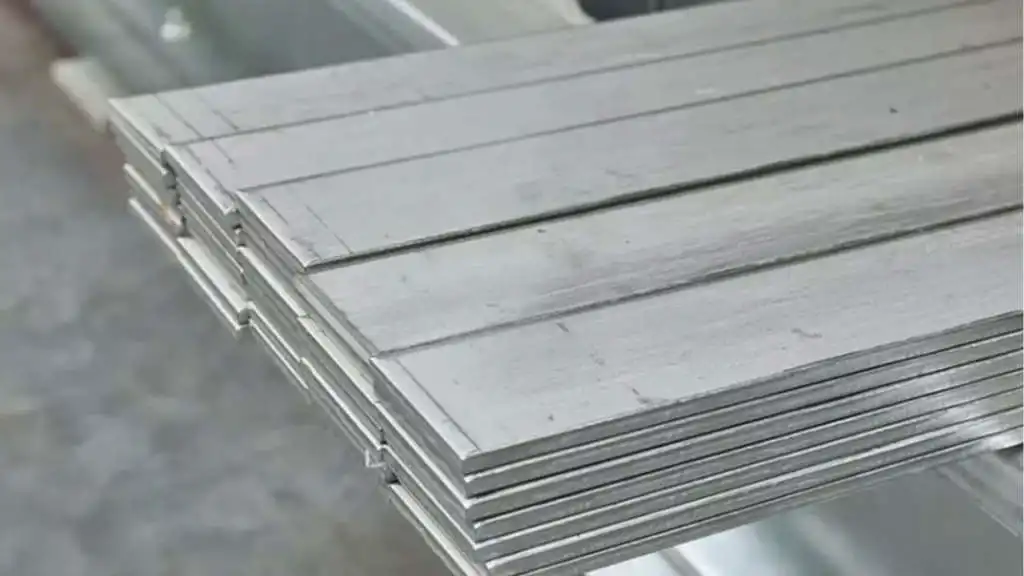

Cold Drawn Flat Iron

What is Cold Drawn Flat Iron?

hot drawn ironto the withdrawal process by reprocessing the logs.cold drawingis called.cold drawingThe purpose of the process is durability, strength, flexibility and smooth outer surface.

Cold Drawn Flat barrecently produced and marketIt is the strongest and most durable iron, especiallysteelconstructionyoursIt is the main carrier and the cornerstone. Usage areas,steelconstructionin their structuresOne of the main purposes of the product used in automotive and automotive structures is to strengthen the supports of the structures, to strengthen the bond between two profiles or between the floor and the ceiling.cold drawingprocedureAs a result of pulling the applied iron through different procedureshot drawingobtained.hot pulls, while being turned into a hot rolled sheetIn terms of structure, it is aimed to be more durable, flexible and smooth outer surfaces.hot llamasIt is a hot rolled flat material in long rectangular sections.hot llamasIt is possible to use it for basic reinforcement in construction and similar structures, and also for decorative purposes in railing iron joinery.

Cold Drawing Flat Bar Procedures

Surface cleaningprocedure:

Thisprocedureas the first stephot rolled billetsIt is applied to remove unwanted crusts and burrs on the surface.high pressure ironThe surface is smoothed by spraying the granules on the surface.

Do not Pullprocedure:

Cleaned logsAfter the first stage, it is prepared to be drawn in the desired caliber size. For this, the material is deposited on the draft beds and their surfaces are coated with a lubricant. Desired size molds are placed.The logs are pulled from the head to the end.passes through the moulds.

Straighteningprocedure:

Withdrawalfrom the procedurecoming outcold drawn materialstrength is ensured by the straightening procedure by passing it between rolls and presses. Round materials are additionally polished.

interruptionprocedure:

At this stagecold drawnThe material is cut to the desired length and measured.

normalize, heatingprocedures:

cold drawnapplied to increase the properties of the material.from proceduressomeone again normalized and materialare warming procedures.. ThisprocedureDuring the process, the outer surface of the material is not affected, it remains the same smoothness. Only the strength of the material increases, the degree of inclination increases.

Quality controlprocedure:

The material leaving the production goes through inspection and control. The aim is the highest quality production and customer satisfaction.

Cold Drawn Flat Iron Quality

ST 37 COLD DRAWING FLAT IRON CHEMICAL COMPOSITION

Chemical Composition (%) | ||||||||||

Standard Equivalent | ERDEMIR | C | Mn | P max. | S max. | Andmax. | Withmax. | N4 | CE(IIW)(6) max. (%) | |

Standard | Quality | Quality No. | max. | max. | max. | |||||

IN 10025-2 | S235JR+AR Special | 3235(2) | 0.17 | 1.4 | 0.035 | 0.035 | 0.4 | 0.55 | 0.012 | 0.35 |

IN 10025-2 | S275JR+AR Special CTB | 3243(3(7(9) | 0.14-0.20 | 1.00 - 1.35 | 0.025 | 0.025 | 0.15 - 0.25 | 0.55 | 0.012 | 0.4 |

IN 10025-2 | S235JR+AR CTA | 4275811th) | 0.17 | 1,2 | 0.025 | 0.035 | 0.03 | 0.55 | 0.012 | 0.35 |

IN 10025-2 | S235J2S235J2+N CTA | 4239(5(8) | 0.17 | 1.4 | 0.025 | 0.025 | 0.03 | 0.55 |

| 0.35 |

IN 10025-2 | S275J2 | 4246(5)7 | 0.18 | 1.5 | 0.025 | 0.025 | - | 0.55 |

| 0.4 |

ST 37 COLD DRAWING MECHANICAL PROPERTIESStandard : EN 10025-2:2019

Mechanical Properties | ||||||||||||||||||

Standard Equivalent | ERDEMIR Quality No. | Rand(min) N/mm2 ( kg/mm2) d(thickness, mm) | Rm(one) N/mm2 ( kg/mm2) d(thickness, mm) | A (%) min. d(thickness, mm) | Coup(3) (Longitudinally) | |||||||||||||

A80 | A5 | |||||||||||||||||

<16 | >16 <40 | >40 <63 | >63 <80 | >80 <100 | <3 | >3 <100 | >1 <1.5 | >1.5 <2 | >2 <2.5 | >2.5 <3 | >3 <40 | >40 <63 | >63 <100 | hot. °C | KVc J(min.) | |||

Standard | Quality(8) | |||||||||||||||||

IN 10025-2 | S235JR+AR | 3237 | 235 (24.0) | 225 (23.0) | 215 (21.9) | 215 (21.9) | 215 (21.9) | 360-510 (36.7-52.0) | 360-510 (36.7-52.0) | 16 | 17 | 18 | 19 | 24 | 23 | 22 | +20 | 27(2) |

S275JR 3244 CHEMICAL COMPOSITION Standard: EN 10025-2:2019

Chemical Composition (%) | |||||||||||||||

Standard Equivalent | ERDEMIR | C d(thickness, mm) | Mn | P | S | And | With | N(one) | CE(IIW) (4) max. (%) | ||||||

Quality No. | <16 | 16<d<40 | 40<d<100 | d (mm) | |||||||||||

Standard | Quality | max. | max. | max. | max. | max. | max. | max. | max. | max. | <30 | 30<d<40 | 40<d<100 | ||

IN 10025-2 | S275JR+AR | 3244(one) | 0.21 | 0.21 | 0.22 | 1:50 | 0.035 | 0.035 | - | 0.55 | 0.012 | 0.40 | 0.40 | 0.42 | |

For S275 and S355 gradesmax. Carbonequivalent (CEV) for %Si ≤ 0.040.02%, for %Si ≤ 0.250.01%can be increased.

S355JR 3252 CHEMICAL COMPOSITIONStandard: EN 10025-2:2019

Chemical Composition (%) | |||||||||||||||

Standard Equivalent | ERDEMIR | C d(thickness, mm) | Mn | P | S | And | With | N(one) | CE(IIW) (4) max. (%) | ||||||

Quality No. | <16 | 16<d<40 | 40<d<100 | d (mm) | |||||||||||

Standard | Quality | max. | max. | max. | max. | max. | max. | max. | max. | max. | <30 | 30<d<40 | 40<d<100 | ||

IN 10025-2 | S355JR+AR | 3252(one) | 0.24 | 0.24 | 0.24 | 1.60 | 0.035 | 0.035 | 0.55 | 0.55 | 0.012 | 0.45 | 0.47 | 0.47 | |

For S275 and S355 gradesmax. Carbonequivalent (CEV) for %Si ≤ 0.040.02%, for %Si ≤ 0.250.01%can be increased.

Weight Chart

Dimensions | 0.70 | 0.80 | 0.90 | 1.00 | 1.20 | 1.50 | 2.00 | 2.50 | 3.00 | 4.00 | 5.00 |

| |||||||||||

(mm) | |||||||||||

10x10 | 0.202 | 0.231 | 0.257 | 0.282 | 0.338 |

|

|

|

|

|

|

12x12 | 0.263 | 0.300 | 0.338 | 0.375 | 0.451 |

|

|

|

|

|

|

15x15 | 0.314 | 0.356 | 0.399 | 0.438 | 0.516 | 0.632 |

|

|

|

|

|

16x16 | 0.334 | 0.382 | 0.426 | 0.471 | 0.557 | 0.696 |

|

|

|

|

|

18x18 | 0.376 | 0.432 | 0.483 | 0.532 | 0.633 | 0.773 |

|

|

|

|

|

20x20 | 0.421 | 0.482 | 0.539 | 0.595 | 0.708 | 0.868 | 1,120 |

|

|

|

|

25x25 | 0.534 | 0.608 | 0.681 | 0.753 | 0.896 | 1,100 | 1,440 | 1.8 | 2.16 |

|

|

30x30 | 0.641 | 0.733 | 0.822 | 0.909 | 1,085 | 1,340 | 1,750 | 2,190 | 2,630 |

|

|

35x35 |

|

|

| 1,070 | 1,267 | 1,570 | 2,070 | 2,540 | 2,860 |

|

|

38x38 |

|

|

|

| 1,367 | 1,690 | 2,220 | 2,740 | 3,100 |

|

|

40x40 |

|

| 1,096 | 1,218 | 1,462 | 1,810 | 2,380 | 2,930 | 3,330 | 4.25 | 5.31 |

45x45 |

|

|

|

|

| 2,050 | 2,690 | 3,330 | 3,800 | 5,066 | 6.33 |

50x50 |

|

|

|

| 1,616 | 2,020 | 2,660 | 3,290 | 3,760 | 4.82 | 6,430 |

60x60 |

|

|

|

| 2,190 | 2,730 | 3,640 | 4,500 | 5,220 | 6.76 | 8.13 |

Dimensions | 1.50 | 2.00 | 2.50 | 3.00 | 4.00 | 5.00 | 6.00 | 6.50 | 7.00 | 7.50 | 8.00 | 10.00 | 12.00 | 14.00 | 16.00 |

| |||||||||||||||

(mm) | |||||||||||||||

70x70 | 3.19 | 4.26 | 5.29 | 6.16 | 8.02 | 9.70 |

|

|

|

|

|

|

|

|

|

75x75 |

| 4.58 | 5.68 | 6.63 | 8.65 | 10.50 |

|

|

|

|

|

|

|

|

|

80x80 |

| 4.89 | 6.07 | 7.10 | 9.28 | 11.30 |

|

|

|

|

|

|

|

|

|

90x90 |

| 5.52 | 6.86 | 8.04 | 10.50 | 12.80 |

|

|

|

|

|

|

|

|

|

100x100 |

|

|

| 8.99 | 11.80 | 14.40 | 17.39 | 18.79 | 20.13 |

|

|

|

|

|

|

110x110 |

|

|

| 9.86 | 13.06 | 16.17 | 19.13 | 20.68 | 22.19 | 23.69 | 25.24 |

|

|

|

|

120x120 |

|

|

| 10.82 | 14.31 | 17.73 | 21.15 | 22.71 | 24.40 | 26.09 | 27.71 |

|

|

|

|

125x125 |

|

|

| 11.27 | 14.89 | 18.44 | 22.02 | 23.65 | 25.44 | 27.18 | 28.96 |

|

|

|

|

150x150 |

|

|

| 13.59 | 17.94 | 22.27 | 26.55 | 28.71 | 30.87 | 32.90 | 35.03 |

|

|

|

|

175x175 |

|

|

| 19.02 | 21.09 | 26.05 | 31.03 | 33.57 | 36.10 | 38.56 | 41.07 |

|

|

|

|

180x180 |

|

|

|

| 21.70 | 26.80 |

| 33.30 |

| 37.20 | 41.50 | 50.70 | 61.50 |

|

|

200x200 |

|

|

|

| 24.20 | 29.90 |

| 37.20 |

| 41.60 | 46.50 | 57.00 | 69.40 |

|

|

250x250 |

|

|

|

|

| 38.30 | 45.70 | 47.90 |

| 53.70 | 60.30 | 74.50 | 88.50 | 103.00 | 115.00 |

260x260 |

|

|

|

|

|

|

| 49.90 |

| 56,00 | 62.80 | 77.70 | 92.20 | 108.00 | 120.00 |

300x300 |

|

|

|

|

|

| 55.10 | 57.80 |

| 64.90 | 72.80 | 90.20 | 107.00 | 126.00 | 141.00 |