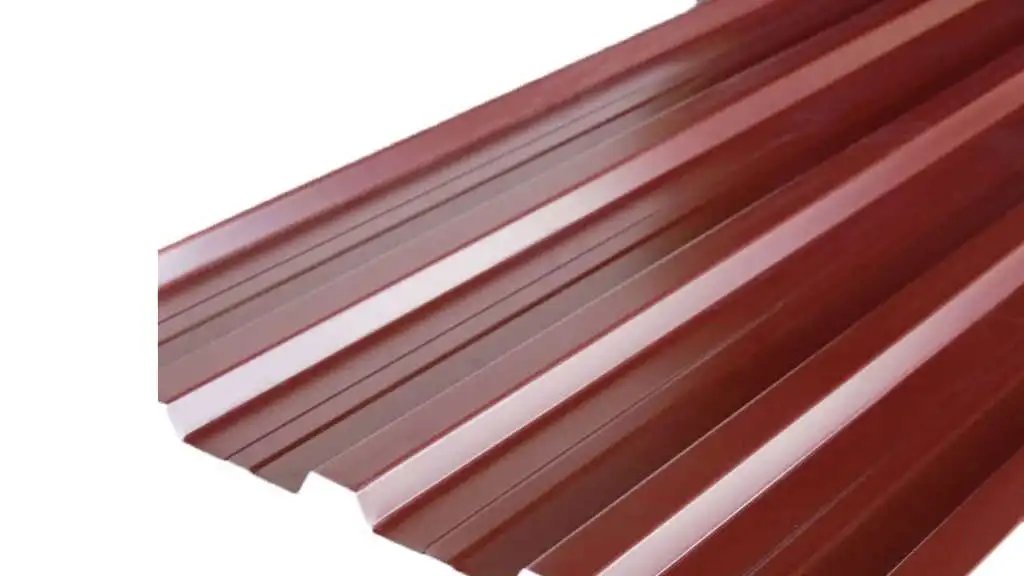

Painted Trapeze

Form : 27-200 - 38-151 - 40-245 - 55-300 - 56-180

Size : 300x300 - 500x500

Thickness : 0.40 - 1.00 mm

Width : 860 - 1000 mm

Length : 1000 - 1300 mm

Painted Trapeze

What is Painted Trapeze?

Galvanizedor painted productsgroove ridge aspectformedis still.painted trape, high strength,galvanized thin steel sac oraluminumIt is produced as dyed and directly without dyeing with a special dyeing technology obtained withpainted trapez sheetsIt forms the basis of the self-supporting roof and facade cladding systems of hall-style buildings.

Galvanized base materialThe multi-layer coating system on thecorrosion protectionprovides. It also increases the surface resistance by providing the opportunity to choose the most suitable aesthetic appearance with its wide coating color options.

Usage Areas and Advantages

This single-layer rectangular cladding would be a good answer for industrial, agricultural or warehouse buildings that do not require thermal insulation. However, indoor and outdoor temperaturevaluesIt is possible to use it in areas where it is needed due to changes (condensation). In cases where the performance of the building will not be interfered withto problemsWhy not. Apart from these, it is frequently used in gyms.

Heat insulated hallsfor, generally, amonginsulated secondary load bearing system (galvanizeprofiles), higher and lowerwith rectangular plates made double skin roof connectiongrease wall covering is applied. Deciding on the most important applicable method characteristics of the facade structure (insulation and substrate type, structural thickness, etc.) requires specific, careful temperature and wetness analysis. There is a chance to use perforated inner rectangular sheet to reduce the noise pollution in the hall, as thisdouble wallfacade system, internalperforated sheetIt will provide higher sound absorption. Painted trapezeflat wall structuresinsidecan also be applied.

- of shopping mallson the roof and walls.

- In industrial establishments.

- In buildings built for military purposes.

- Roofs and structures of farm and vineyard houses.

- in gyms.

- In social facilities.

Features and Advantages

- Roof and facadequick and simple assembly.

- Light weight of galvanizationvia the carrierfrom the constructionProvides savings and easy installation.

- The variety of forms and colors gives the customer the opportunity to choose..

- It is environmentally friendly due to its recycling feature..

- Keeps fireproof and simple soldering.

- Painted trapezoidal sheet 12 It can be produced in desired length up to meters.

- Paintings on galvanized steel extend the life of the galvanized layer..

Forms

27/200 trapezoidal formis the most economical and common form.Galvanized sheetor aluminumand coilcoatingsystemwith or without paint,0,50 – 1 mmbetweenIt can be produced in different thicknesses and colors. Net footprint800 or 1000 mmis .

38-151 Trapeze Form

38/151 trapezoidal form, mid-spanin loveIt is the ideal form for them.Galvanized sheetor aluminumand coilcoatingsystemwith or without paint, 0,50 – 1 mmIt can be produced in different thicknesses and colors. Net footprint906 mmis .

40-245 Trapeze Form

40/245 trapezoidal formis one of the most cost-effective forms for roofing.Galvanized sheetor aluminumand coilcoatingsystemIt can be produced in different thicknesses and colors between 0.50 – 1 mm, as painted or unpainted. Net coverage area is 980 mm.

55-300 Trapeze Form

55/300 trapezoidal formIt is the most suitable form for wide spans and heavy loads on roofs.Galvanized sheetor aluminumandcoilcoatingsystemwith or without paint,0,50 – 1 mmIt can be produced in different thicknesses and colors. The net covering area is 900 mm.

56-180 Trapeze Form

56/180 trapezoidal formIt is a suitable form for wide spans and heavy loads on roofs.Galvanized sheetor aluminumand coilcoatingsystemwith or without paint,0,50 – 1 mmIt can be produced in different thicknesses and colors. Net footprint720 or 900mm'is.