Printed Sheet

Euro Quality : S235JR - S235JR(Cu) - RST37-2

Erdemir Quality : 3237 - 3281 - 3937

Size : 100x2000 - 1250x2500 mm

Wall Thickness : 1.20 - 1.50 mm

Printed Sheet

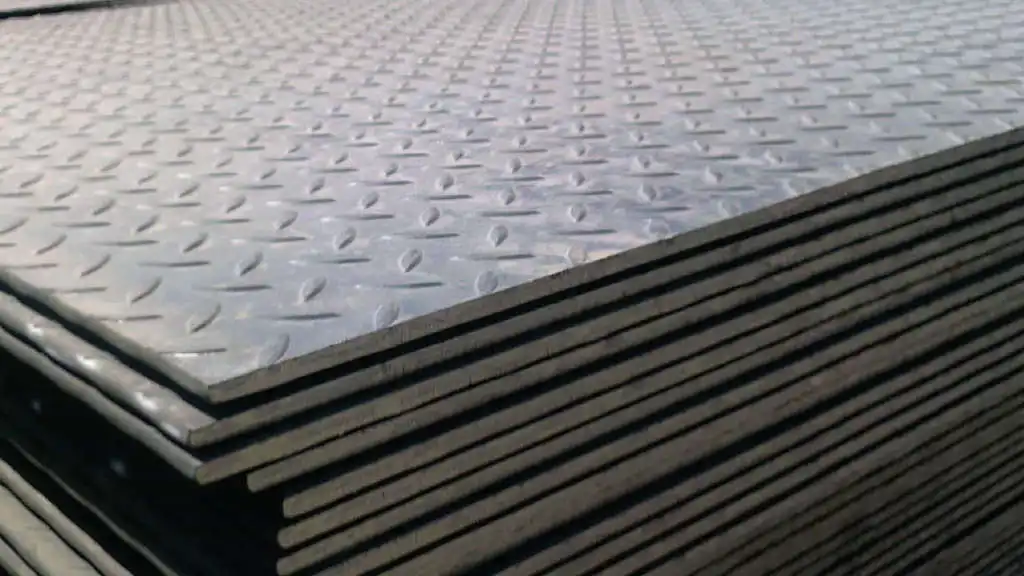

What is Printed Sheet?

printed sheetmodels with different alternativeswith their designsare manufactured products. Commonly used in the iron and steel industryprinted sheetmethod and mechanical properties may vary depending on the type of product you prefer. A seriesfrom the procedurewhich finally takes the form of a sheet after passing throughprinted sheetsAccording to the usage areas, the prints become ready to be used efficiently.

Printed sheets, which are highly preferred in domestic and international markets0 mm to 2,00It has thicknesses between mm. It is known that their length can reach up to 4000 mm. Able to reveal a flexible range of motion regarding the issue of dimensions.printed sheets It is offered to you according to your personal preferences, as well as according to standard sizes.

Quality

Chemical Composition (%) | ||||||||||

Standard Equivalent | ERDEMIR | C | Mn | P max. | S max. | Andmax. | Withmax. | N4 | CE(IIW)(6) max. (%) | |

Standard | Quality | Quality No. | max. | max. | max. | |||||

IN 10025-2 | S235JR+AR Special | 3235(2) | 0.17 | 1.4 | 0.035 | 0.035 | 0.4 | 0.55 | 0.012 | 0.35 |

IN 10025-2 | S275JR+AR Special CTB | 3243(3(7(9) | 0.14-0.20 | 1.00 - 1.35 | 0.025 | 0.025 | 0.15 - 0.25 | 0.55 | 0.012 | 0.4 |

IN 10025-2 | S235JR+AR CTA | 4275811th) | 0.17 | 1,2 | 0.025 | 0.035 | 0.03 | 0.55 | 0.012 | 0.35 |

IN 10025-2 | S235J2S235J2+N CTA | 4239(5(8) | 0.17 | 1.4 | 0.025 | 0.025 | 0.03 | 0.55 |

| 0.35 |

IN 10025-2 | S275J2 | 4246(5)7 | 0.18 | 1.5 | 0.025 | 0.025 | - | 0.55 |

| 0.4 |

Descriptions

- The quality specified in this table is produced at İsdemir facilities within the framework of agreements made with customers.

- In this quality, it is produced in such a way that roll breakage does not occur.

- Mechanical testing is not performed according to production practices.

- In the chemical composition of the steel, min.%0.020 AlN upper limit value is not applied for grades with

- These grades are produced as fully stagnant and Al/N minimum2:1rate.

- Carbon equivalent, CEV (IIW) % = C + Mn / 6 + (Cr +Mo + V) / 5 + (In+ With) /to the formula 15calculated accordingly.

- For S275 and S355 gradesmax. Carbonequivalent (CEV) for %Si ≤ 0.040.02%, for %Si ≤ 0.250.01%is increased.

- It is suitable for galvanized coating as “Category A”. In category A, the limit of Si ≤ 0.030% and Si+2.5P ≤ 0.090% applies

- It is suitable for galvanized coating as “Category B”. In category B, the limit of Si 0.14≤ Si ≤0.25% applies.

- In line with production practices, the suitability for galvanized coating can be considered subject to negotiation at the order stage. Galvanizedsuitability for coating sınıfları Kategori A sınıfında Si ≤ 0.030% ve Si+2.5P ≤ 0.090% limiti, Kategori B sınıfında Si 0.14≤ Si ≤0.25% limiti, Kategori D sınıfında Si 0.25< Si ≤0.35% limiti olarak uygulanır.

- Max. It is produced up to 8 mm thickness.

Usage Areas

Printed sheetsIt is preferred in different sectors.Printed sheets used on the base surfacePrinted sheets, which make non-slip surfaces possible, are also used in seaside facilities with walkways, truck and truck bodies, ramps and ship surfaces. Printed sheets used on the exterior of buildings in the form of decoration are the sheets that you can encounter in many different points of daily life.

Printed sheets are products offered to you at world quality standards. The prices of the printed sheets, each of which stands out with their different usage areas, are priced differently according to the method features of the product you prefer. Prices include reasonable price options for each person's budget.

Weight Chart

Thickness mm | 1000x2000 mm kgs | 1250x2500 mm kgs | 1500x3000 mm kgs |

1.5/2.5 | 27.55 | 43.05 | 61.99 |

2/3 | 35.40 | 55.31 | 79.65 |

3/4 | 51.10 | 79.84 | 114.98 |

4/5 | 66.80 | 104.38 | 150.30 |

5/6 | 82.50 | 128.91 | 185.63 |

6/7 | 98.20 | 153.44 | 220.95 |

7/8 | 113.90 | 177.97 | 256.28 |

8/9 | 129.60 | 202.50 | 291.60 |

9/10 | 145.30 | 227.03 | 326.93 |

10/11 | 161.00 | 251.56 | 362.25 |

12/13 | 192.40 | 306.63 | 432.90 |